Beverage / Isobaric / Beer Bottle Filling Machine

- Mobile: +86 15851631082

- Email: bonnie@jinri-packaging-machinery.com

Beverage / Isobaric / Beer Bottle Filling Machine

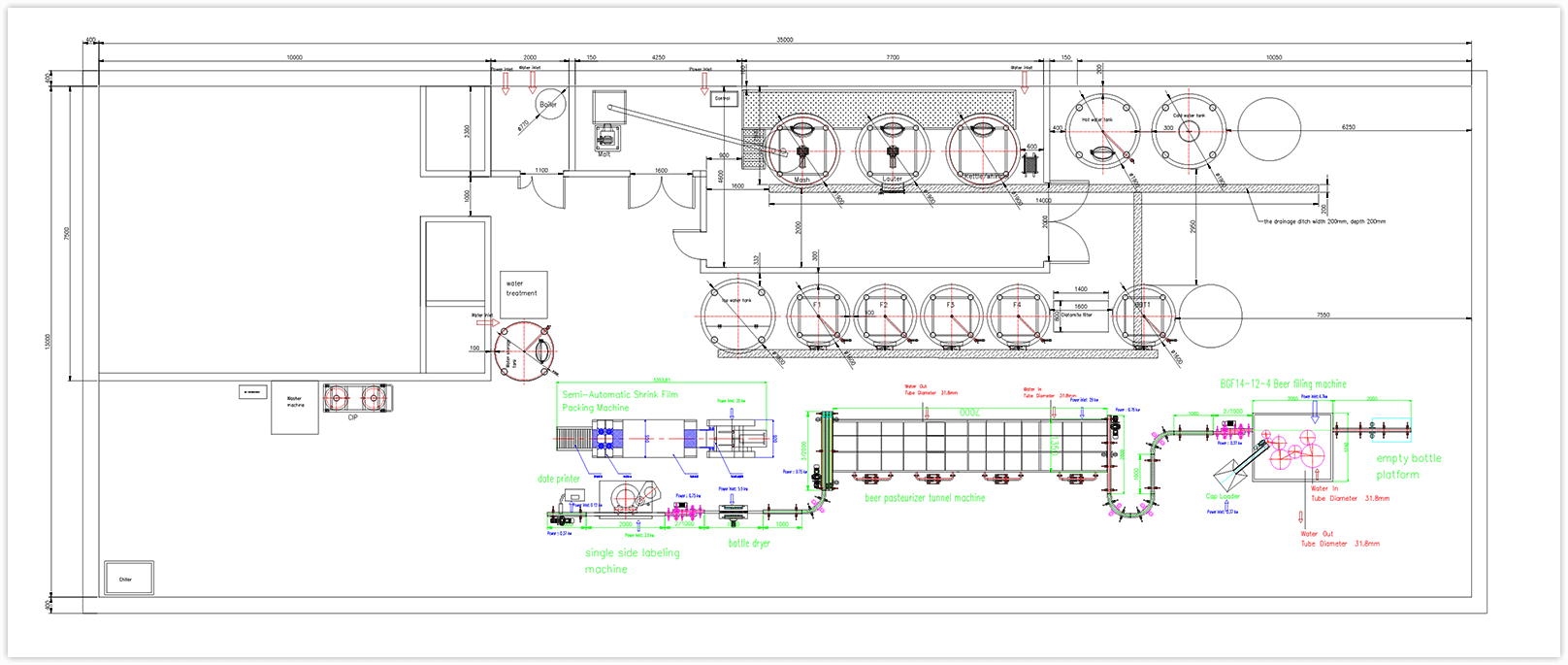

BGF series is a glass bottle beer filling three-in-one machine independently developed by our company. The filling capacity is 300-20000b/h, which is the hottest sold in the production of small and medium-sized craft beer manufacturers. In line with national food and drinking standards, it has a good reputation in the beer fileds and is very popular among domestic and foreign customers.

At the same time, our engineers have rich practical experience and can design an optimal production plan for each customer. When the equipment arrives at the customer's factory, we will arrange the engineers to go to the buyer's factory for equipment debugging and personnel training.

Saccharification equipment in the preparation of wort, wort

naturally filtered to obtain a more clear path, the rut of beer will be

higher. So we use the idea of a large brewery miniaturization

design. Filter through the buffer tank for filtration. Through the role

of natural gravity, through the buffer tank, obtained wort, into the boiling pot.

Will not be due to suction, leading to malt layer of absorption, resulting in filtration difficulties;

High stability of filtering speed and good effect of the filter layer of wheat grains, wort ruthless;

Convenient operation even for novice;

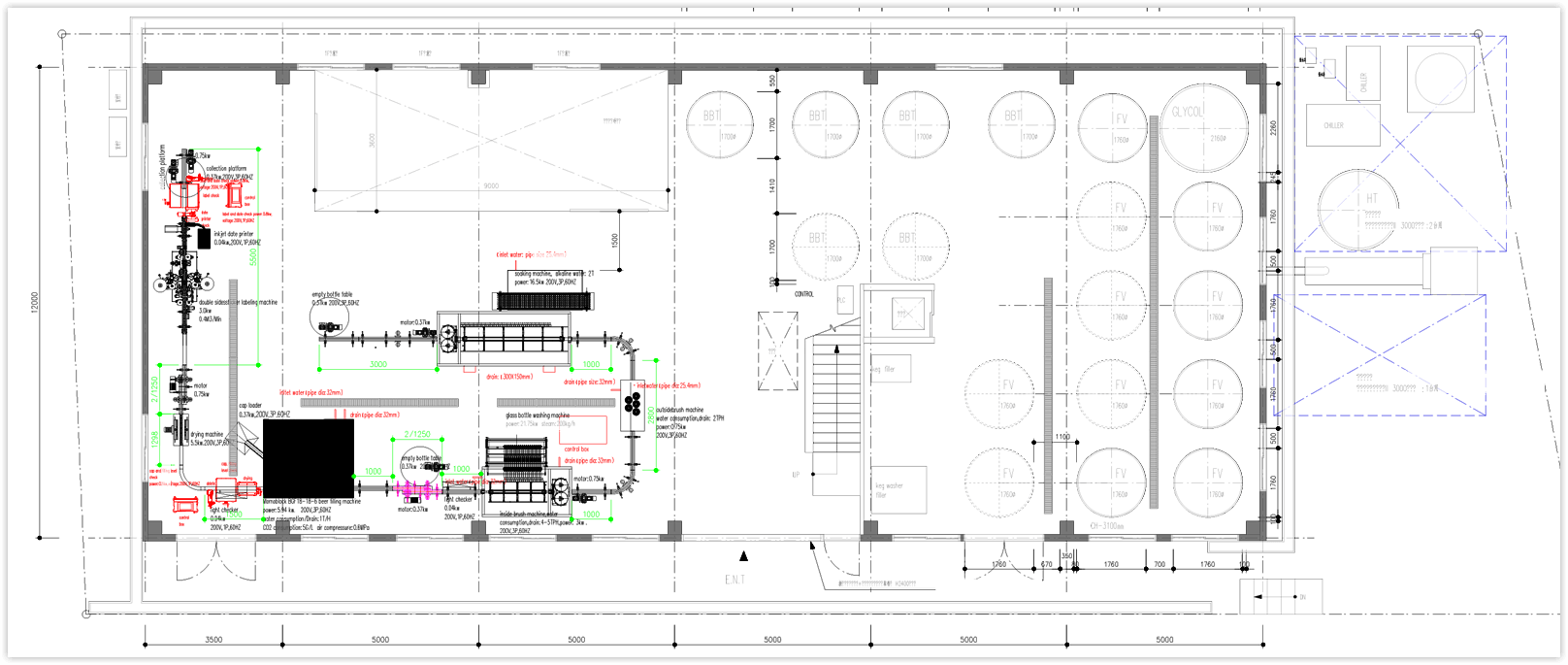

The fermenter has double safety effect;

The mechanical components on the top play the role of a negative pressure protection, which can effectively preventthe misuse of negative pressure in the tank and the damage of the tank;

The tank interior is not easy to be contaminated by bacteria when thermal cleaning. Saccharification equipment aopts a series of high strength CIP cleaning technology without manual cleaning, which can reduce labor costs.

Used in food and beverage/beer industry, chemical industry; supporting three-in-one filling machine, All types of empty can, glass bottle can be unloaded, the output can be connected to the chain or duct.

The mechanical structure is simple, small footprint, large production capacity;

The whole machine PLC control, automatic operation;

To adapt to a variety of stacking and bottle type, easy to adjust;

Multiple security protection, with touch screen control;

The use of high-quality conveyor chain sub-transmission, into the paragraph can be arbitrarily lengthened;

Motor, cylinder drive and control all imported brand-name components;

Try to use 304 materials, machine beautiful and generous.

We have developed the latest BGF series glass bottle beer washing filling capping 3-in-1 machine in accordance with the technological requirements for packaging beer in glass bottle by adopting advanced technologies both at home and abroad. Meanwhile, we are able to provide complete high-efficiency beer filling production line for the beer breweries.

With high pressure frothing device, it is capable of double vacuum-pumping;

Using combined transmission stepless speed control to extend the speed modulating scope;

High transmission efficiency, low noise and long lifetime;

The caps are free from deforming, and can flow smoothly in large quantities during transmission, with the function of pre-covering which allows stable and reliable bottle transferring;

The function of automatic loading helps lower the bottle breakage;

Suitable for different sizes of bottles;

To ensure precise liquid level and reliable filling.

Beer pasteurization tunnel, warming and cooling tunnel, is specially designed and used for bottled beer after filling. Which through sterilization, warm preservation, cooling achieve prolong the shelf life, especially the secondary sterilization equipment for automatic production line. According to users of different products of different heating, sterilization, warm preservation, cooling process requirement, to design a different process, meet the technological requirements, according to user requirements, configuration of the corresponding high precision automatic control system.

The machine frame is made of stainless steel, the overall structure is compact and the appearance is wholesome and beautiful;

High quality plastic engineering belt chain plate, can be long-term work under the high temperature of 100 OC;

Pt100 temperature sensor, measurement accuracy is high up to +/- 0.5 OC;

The multi-process combination, the process is reasonable, can handle various materials;

The pasteurized temperature is controlled by the German Siemens PLC;

The frequency conversion control can be adjusted according to the production process;

PP bottles, plastic bags, paper boxes, bottles, cans and other products roof the discharged, configuration and automated conveyor line connection transition smoothly.

Drying machine is the pressure generated by the vortex air pump air through the air knife hair spike of high-speed wind curtains, drops the bottle blew the body, easy bottle labeling and packing. (With food hygiene requirements of the materials), 304 stainless steel tank.

Power of motor: 5.5KW

Weight: s150kg

Blowing rater: 546-716m3/h

Machine size: L900*W650*H1650mm

Material: SUS304

Heavy-duty construction utilizes oversized drive components combined with an aluminum and stainless steel base frame for years of dependable service.

Various product infeed systems are available that provide precise product spacing and orientation. It can be used stand alone or integrated in-line and matching filling equipment speeds.

Advanced high torque micro-stepping driven applicators include ratio-offset and speed-following capability for accurate and reliable application of a wide variety of label materials.

Designed for the application of front and/or back panel labels with the capability to label containers that are round, square, oval or rectangular.

The sensor detect the product, transmit the signal to labeling control system;

After the signal has been processed by the PLC, a label is send out at an appropriate time and attach on a desired position of the container;

The container go through the press plate unit, the press wheel lead the rotation of container, the label is pressed to fit smoothly, the labeling operation is finished.

The all-new Videojet 1220 CIJ printer is engineered to keep your line up and running longer. It’s designed for customers who print six hours to eight hours per day, five days per week—providing 9,000 hours* of production before required preventive maintenance.

Advanced capabilities

Clear advantage in print quality

Low running costs

Easy predictable maintenance

Superior environmental protection

Packaging Flow:

Feeding→ Pushing Bottles→ Film Covering And Sealing→ Shrinking→ Cooling

The film covering and sealing device adopt advanced heat sealing and heat cutting structure, with advantages of sealing firmly, neat edge and good joined performance;

The sealing and cutting part driver by cylinder, with guide columns at both ends, which can guarantee the process steadily and steadily;

Special protection function: when obstruction on the sealing and cutting position, the equipment will be prevent and alarming at the same time to protect the package from damaged;

Feeding trough adopts flat feeding type;

The heating part adopts high-quality stainless steel cooling fin, with advantage of steady & homogeneous heat dissipation and long use life;

PID temperature controller: accurate and energy-saving;

The whole equipment controlled by automatic controller, with steady and reliable production, can apply to working long hours and non-stop.

The main features are automatic binning, automatic vertical box molding, automatic folding cover, automatic sealing function.

The use of side into the bottle: a small footprint, simplifying the transport system before the packing machine, reducing the cost of investment equipment;

The use of three decompression: product decompression, to grasp the bottle head and product alignment accurate, grasping bottle success rate of 100%; products into the packing process in a pressure-free delivery state, the basic elimination of crushing phenomenon;

The use of German IGUS linear positioning system: high positioning accuracy, the movement is accurate, effectively reduce the impact of equipment operation and vibration, greatly improving equipment stability and reliability; lubrication-free, maintenance-free, good health conditions.

From Colombia

Colombia customer, main want to sell beer bottle in local market, we make a cooperate in 2018.

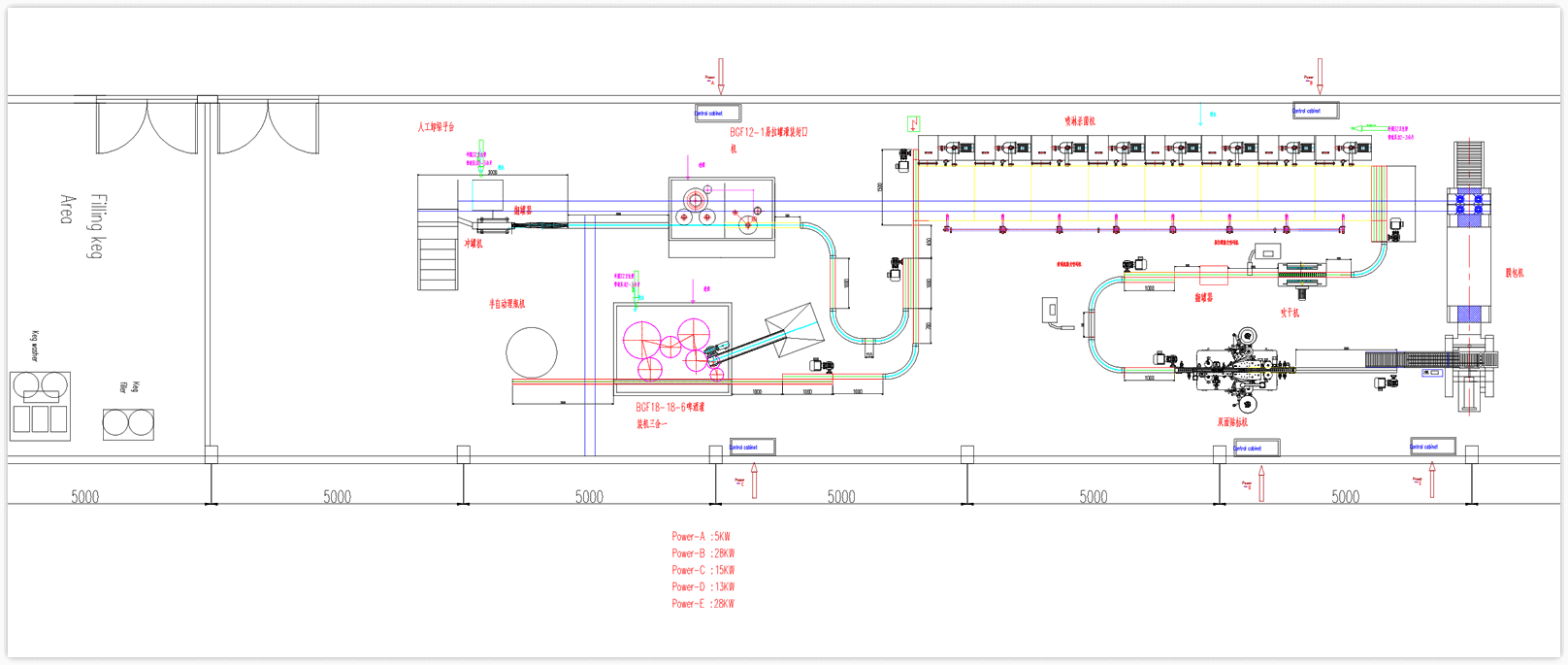

Machine: BGF14-12-4 Beer Filling Line

From Ukraine

Ukrain customers, mainly producing beer to all parts of Europe, we are cooperating in 2017.

Machine: BGF18-18-6 Beer Filling Line

From Japan

Japan customer,main want to sell beer bottle in kanazawa market,we make a cooperation in 2018.

Machine: BGF18-18-6 Beer filling line

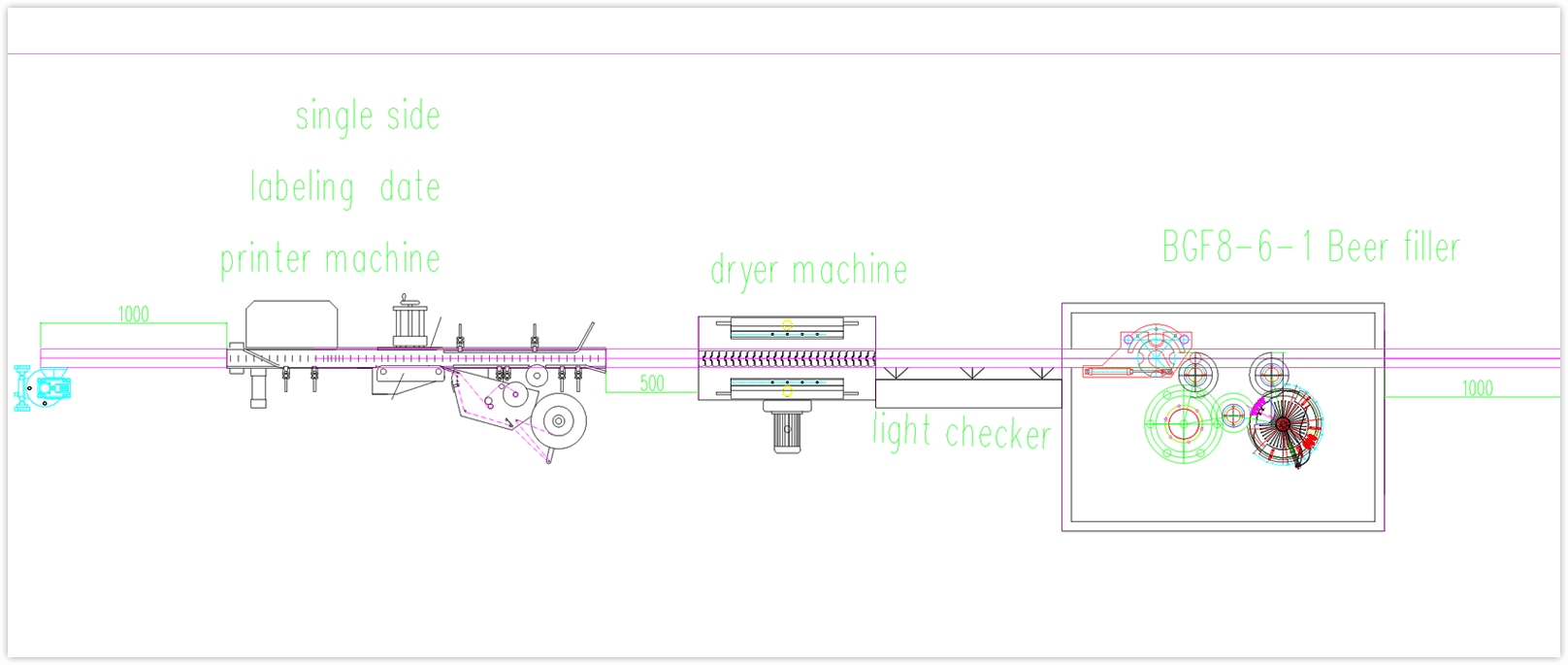

From Lebanon

Lebanon customer,main want to sell beer bottle in local market,we make a cooperate in 2018.

Machine: BGF8-6-1 beer filling machine

By continuing to use the site you agree to our privacy policy.