Beverage / Isobaric / Beer Bottle Filling Machine

- Mobile: +86 15851631082

- Email: bonnie@jinri-packaging-machinery.com

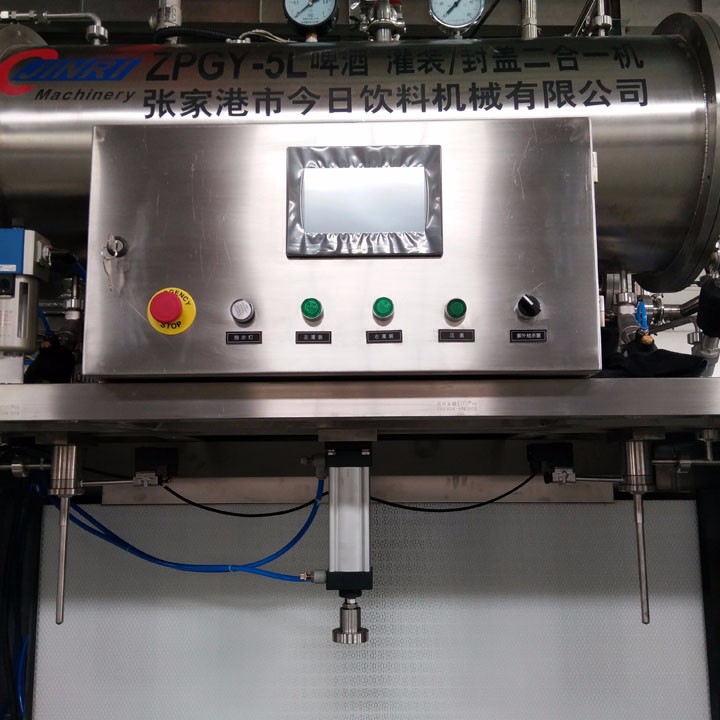

Beverage / Isobaric / Beer Bottle Filling Machine

Manual 5L beer can filling and sealing machine is also popular in small brewery factory. This product main sell to hotel, resturant and so on. Our filling machine principle is same with bottle beer filling process, vacuum, fill CO2, stable pressure, fill beer, release pressure, pressure capping machine.

This machine is mainly composed of the following parts:

1. frame

2. Filling part

3. Pressure capping part

4. Air purification section

5. Pipe and CIP cleaning section

6. Electrical control section

7. Pneumatic control section

Features :

1. This equipment is specially designed for the filling and sealing of 5L beer fresh-keeping containers (including stainless steel, plastic storage barrels and beer barrels). The equipment can automatically complete the filling and sealing work in a sterile environment and prolong the shelf life of the beer.

2. The control unit of the machine adopts Weilun touch screen and Mitsubishi PLC integrated machine for automatic control of the whole process. All control parameters (time values) can be adjusted without downtime. High degree of automation, adjustment is very convenient and reliable!

3. All parts of the machine are made of stainless steel, and the parts in contact with the materials are made of sanitary stainless steel, which meets the national sanitary requirements.

4. CO2 backup pressure: Replace the air in the barrel to achieve isostatic filling to prevent the loss of carbon dioxide in the beer.

5. Filling: Long tube filling technology reduces beer oxidation during filling, and the filling process is stable and accurate.

6. This machine has a complete CIP system, and is equipped with ultraviolet disinfection device and air purification system in the filling gland area to ensure the hygiene of the filling process and prevent the second pollution of beer.

7. This machine does not need to use sterile room, it has small floor space and is equipped with movable roller to save space and save investment.

Technical parameter:

Filling head: 2

Capping head:1

Machine size:1550mm×1000mm×2200mm

weight:800kg

capacity:50-120bph

Filling way:isobaric filling

Beer source pressure:0.2 ---- 0.3Mpa

Air source pressure:0.7 ---- 0.9Mpa

CO2 pressure:0.2 ---- 0.3Mpa

Voltage :AC380V 50Hz

Manually beer 5L can filling and capping machine picture show:

By continuing to use the site you agree to our privacy policy.