Beverage / Isobaric / Beer Bottle Filling Machine

- Mobile: +86 15851631082

- Email: bonnie@jinri-packaging-machinery.com

Beverage / Isobaric / Beer Bottle Filling Machine

Manually put the washed bottle on the bottle holder and press the filling button on the touch screen to fill the beer. Manually place the filled bottle on the cap and place the bottle on the cap bottle holders on both sides. (There are 2 caps on each side of the machine), press the gland button on the touch screen, and press the bottle cap.

This device is specially designed for the filling of the screw cap for plastic bottle, crown caps for glass bottles of beer. The device is simple to operate, has low investment, and has a small footprint. Adapt to bars, shops, restaurants and other places.

The control unit of the machine adopts Weilun touch screen and Mitsubishi PLC integrated machine for automatic control of the whole process. All control parameters (time values) can be adjusted without downtime. Simple and reliable!

Manually put the washed bottle on the bottle holder and press the filling button on the touch screen to fill the beer.

Manually place the filled bottle on the cap and place the bottle on the cap bottle holders on both sides. (There are 2 caps on each side of the machine), press the gland button on the touch screen, and press the bottle cap.

After the gland is over, manually remove the bottle from the gland bottle holder.

| Filling head | 4 |

| Capping head | 4 |

| Work surface height | 700mm |

| Size | L*W*H= 1300mm x 600mmX2200mm |

| Weight | about 200kg |

| Speed | 200-300b/h |

| Filling way | isobaric filling |

| Power | 0.37KW |

| Beer source pressure | 0.2 ---- 0.3Mpa |

| Air source pressure | 0.6 ---- 0.8Mpa |

| CO2 pressure | 0.6 ---- 0.8Mpa |

| Voltage | AC380V 50Hz |

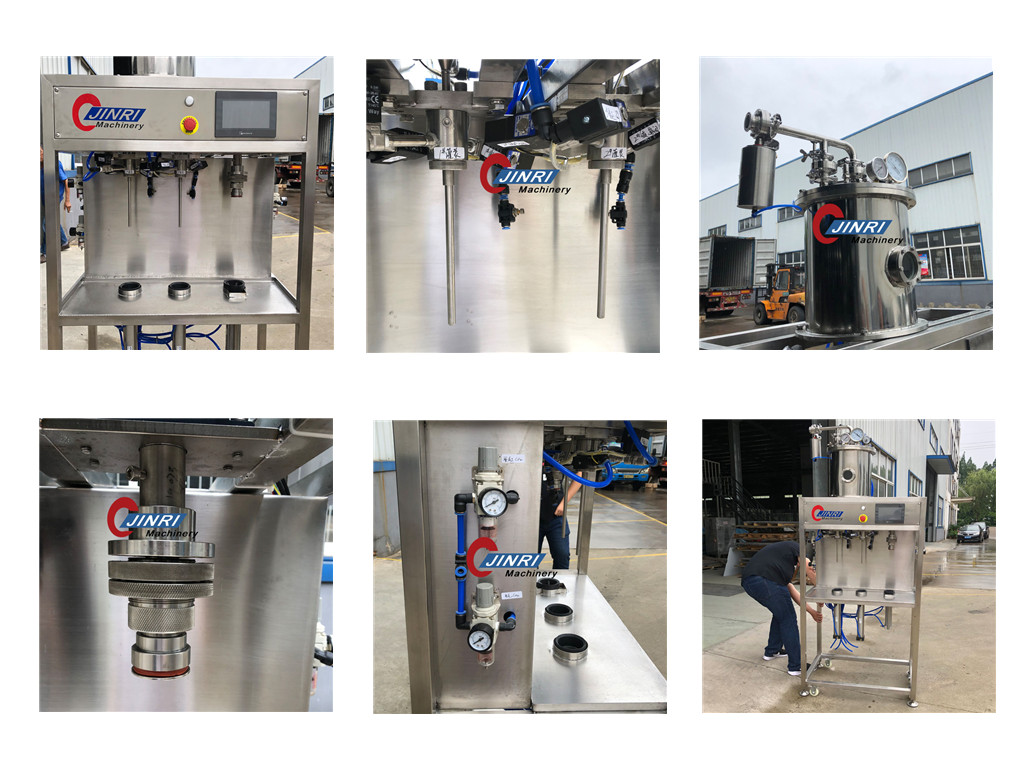

Manually glass bottle beer filling machine picture shows:

By continuing to use the site you agree to our privacy policy.